Troubleshooters.Com

Presents

Troubleshooting

Professional

Magazine

Volume 8 Issue

3, Summer,

2004

Choosing the Right Tool

|

Copyright (C) 2004 by Steve Litt. All rights

reserved.

Materials from guest authors copyrighted by them and licensed for

perpetual

use to Troubleshooting Professional Magazine. All rights reserved to

the

copyright holder, except for items specifically marked otherwise

(certain

free software source code, GNU/GPL, etc.). All material herein provided

"As-Is".

User assumes all risk and responsibility for any outcome.

[ Troubleshooters.Com

| Back Issues | Linux Productivity Magazine ]

It's a poor workman who blames his tools. -- Unknown

The good workman finds better tools. -- Steve Litt

|

CONTENTS

Editor's Desk

By Steve Litt

Impossibly buried, there was just no way to get to the clamp holding

the upper radiator hose to the radiator on my wife's GMC Suburban.

Nestled snugly between the radiator, the grill and the wiper fluid

reservoir, no pliers, no screwdriver, no twisted coathanger could have

sprung this spring clamp. Removal of the wiper fluid reservoir seemed

the quickest option -- or else just cutting the hose, prying the clamp,

and replacing everything.

Aaron, the radiator tech looked at the situation, went into the shop,

and brought out a bizarre looking tool. It was like a tiny flat

guillotine connected to a bicycle brake cable, itself connected to a

pliers like device to pull the cable. Aaron slipped the guillotine

over the clamp's squeeze handles, squeezed the pliers, and effortlessly

slid the clamp down the hose and removed the hose. Ellapsed time: 1.5

minutes. One minute to retrieve the tool, and 30 seconds to do the job.

Ever since writing the Winter 2003 Troubleshooting Professional

Magazine, titled "Toolsmanship", I've been much more conscious of the

role of tool use in productivity. I've seen many cases where using the

right tool could cut out 9/10 or more of the time required for a task.

This issue of Troubleshooting Professional Magazine is devoted to

choosing the right tool for the job. So kick back, relax, and enjoy the

read. And remember, if you're a Troubleshooter, this is your magazine.

A Trip to Young's

Automotive

By Steve Litt

A recent trip to Young's Automotive in Longwood, one of Orlando's

premier radiator

and cooling system shops, provided me more than enough incentive to

write this issue of Troubleshooting Professional Magazine. The owner is

named Craig, and his main technician is named Aaron. They're both

extremely knowledgeable, with great diagnostic skills. I could write an

article about their cooling system troubleshooting prowess, but this

month's theme is tool choice, and Young's Automotive is a prime example

of excellent tool choices.

It started out simply enough. I wanted to change out the Dex-cool

coolant on my wife's GMC suburban for ethylene glycol. They inspected

the car and found evidence of leakage out the lower weap hole of the

water pump. After hearing that, my wife wanted the water pump changed.

I could have changed the water pump myself, but it would have taken me

a week. Aaron did it in an hour.

Of course, Aaron had the advantage of being a pro, and knowing what

needed to come off and what didn't. But more significant was his tool

choice and toolsmanship.

Some of it was a nobrainer. He had an air driven wrench. He had a

flexible extension on which to attach sockets. He had the right sockets

for the job. He had the fan shroud off in a minute.

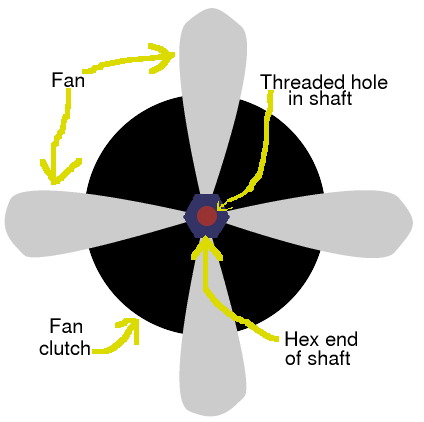

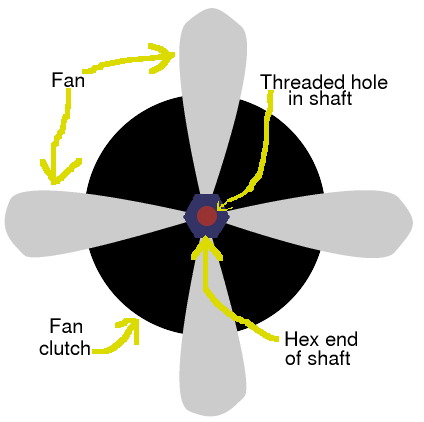

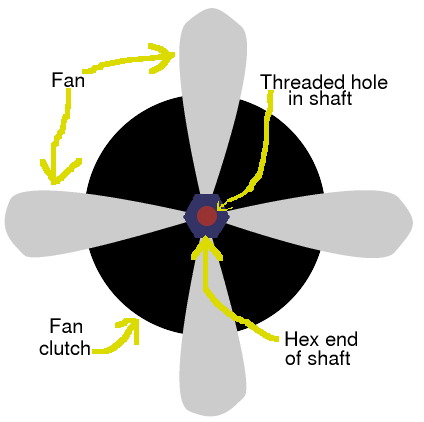

Removing the fan and fan clutch was a little tougher. The fan clutch

screws on to the threaded shaft of the water pump. The end of the fan

clutch

shaft is a hex on which to grab with a wrench.

|

|

Fan

assembly, side view

|

Fan

assembly, back view

|

So all you need to do is place a wrench on the hex and turn

counterclockwise. NOT!

Number one, the fan clutch shaft is screwed tightly to the water pump

shaft, because the turning of the water pump continuously tends to

tighten

the threaded connection. Worse yet, if you turn the hex, the water pump

will just turn with it. The fan belt, which contacts a pulley bolted to

the fan belt shaft, stops the pulley turning to a

degree, but not much.

So Aaron used an air powered hammer to turn a wrench. But not just any

wrench. It was a wrench with a notch built into the handle. You place

the head of the air hammer in that notch. It looked like this:

It took a couple minutes, but he hammered it loose. Once loose, he

could easily unscrew it.

One of Aaron's best allies in this repair was his swivel extension,

onto which he placed the sockets. This freed him from the necessity of

aiming the socket "just so", which in many cases would have been

impossible. Another timesaver was his right angle air wrench, a slow

speed, high torque job that could fit anywhere. That's how he removed

the pulley from the water pump shaft after removing the fan assembly.

Removing the water pump itself required exactly the right socket, and a

heavy hand on the air wrench, because naturally the bolts were rusted

in. Had the corrosion been worse, perhaps penetrating oil would have

been called for.

As I mentioned, by far the most impressive tool was his hose clip

releaser, consisting of a pliers like device connected to a guillotine

type device with a bicycle brake cable. It looked like this:

You put the guillotine looking part over the "handles" of the spring

clip, squeeze the pliers, and the guillotine sqeezes the clip handles

together, freeing the clip.

There were other impressive tools, but I've forgotten them.

You Know You

Need a Better Tool When...

By Steve Litt

Frustration is your best indicator that you need a better tool. If some

aspect of the system converts what seemingly should be easy into a

knucklebusting bloody battle, you need a better tool.

Another excellent indicator is procrastination. If you dread taking a

measurement because you need to spend a half hour on disassembly, or

there's one nut you just can't get loose, you need a better tool. If

you perform zillions of diagnostic tests to make up for the one that

would have cleanly divided the root cause scope in half, you need a

better tool.

When you need a better tool, find one...

Finding Better Tools

By Steve Litt

Tool catalogs are your friend. Look through tool catalogs. See what's

available, and what situations call for such a tool. If the situation

is something you run into frequently, and without the tool the

situation is an excercise in frustration, order the tool immediately.

Otherwise, make a mental note of the tool and the situation, so when

the time comes you can order the tool.

Friends are your friend. If there's a situation that regularly costs

you too much time, ask your friends what they do to solve such

problems. Chances are one will have a tool that's just right.

Your own ingenuity is your friend. If you can't find a tool, make it.

What else are coathangers, magnets and tape made for. If you're at all

familiar with computer programming, you can make software tools to see

inside what would otherwise be black boxes. You can either put together

existing tools to fill a new need, or if you are a fairly sophisticated

programmer you can write a tool from scratch.

Leverage is your friend. Using sturdy pipes to extend wrenches is a

time honored tradition. Pipe wrenches "grab" where nothing else can.

Strongarming can backfire and should be used only in a last resort, but

when needed, it's useful.

Vision enhancers are your friend. There are cable mounted lamps that

can shine way inside the machine. Magnifying glasses can help with

small parts. Mirrors show you what otherwise would be unseen, and can

be used to best effect with proper light sources. Digital cameras are

your friend, as their pictures can be zoomed and shrunk to see the big

picture, or the connector number silkscreened on the motherboard.

Knoppix is your friend. Knoppix is a CD-based Linux distribution that

boots without disturbing the operating system on the hard disk.

|

WARNING

There ARE ways to make Knoppix disturb the underlying operating system,

and it's theoretically possible that an error in Knoppix could make it

disturb the underlying operating system even without user error, so

always back up and follow other damage control procedures to the extent

justified by the situation.

|

With Knoppix, you can explore various disk partitions, whether they're

Linux or Windows. You can delete problematic files or edit

configuration files. When editing or deleting, the partition must be

mounted read/write (which involves some degree of risk), and you must

unmount the partition in order to "finalize" the edit or deletion.

Knoppix is great for investigating video problems, network problems,

sound problems and the like. It's great for obtaining one last backup

(via data transfer to another computer) on a hard disk stable enough to

copy data from but not stable enough to run an operating system.

Always be on the lookout for new tools to speed your work.

Letters to the Editor

All letters become the property of the publisher (Steve Litt), and

may

be edited for clarity or brevity. We especially welcome additions,

clarifications,

corrections or flames from vendors whose products have been reviewed in

this

magazine. We reserve the right to not publish letters we deem in

bad taste

(bad language, obscenity, hate, lewd, violence, etc.).

Submit letters to the editor to Steve Litt's email address, and be

sure

the subject reads "Letter to the Editor". We regret that we cannot

return

your letter, so please make a copy of it for future reference.

How to Submit an Article

We anticipate two to five articles per issue, with issues coming out

monthly.

We look for articles that pertain to the Troubleshooting Process, or

articles

on tools, equipment or systems with a Troubleshooting slant. This can

be

done as an essay, with humor, with a case study, or some other literary

device.

A Troubleshooting poem would be nice. Submissions may mention a

specific product,

but must be useful without the purchase of that product. Content must

greatly

overpower advertising. Submissions should be between 250 and 2000 words

long.

Any article submitted to Troubleshooting Professional Magazine must

be

licensed with the Open Publication License, which you can view at

http://opencontent.org/openpub/.

At your option you may elect the option to prohibit substantive

modifications.

However, in order to publish your article in Troubleshooting

Professional

Magazine, you must decline the option to prohibit commercial use,

because

Troubleshooting Professional Magazine is a commercial publication.

Obviously, you must be the copyright holder and must be legally able

to

so license the article. We do not currently pay for articles.

Troubleshooters.Com reserves the right to edit any submission for

clarity

or brevity, within the scope of the Open Publication License. If you

elect

to prohibit substantive modifications, we may elect to place editors

notes

outside of your material, or reject the submission, or send it back for

modification.

Any published article will include a two sentence description of the

author,

a hypertext link to his or her email, and a phone number if desired.

Upon

request, we will include a hypertext link, at the end of the magazine

issue,

to the author's website, providing that website meets the

Troubleshooters.Com

criteria for links and that the

author's

website first links to Troubleshooters.Com. Authors: please understand

we

can't place hyperlinks inside articles. If we did, only the first

article

would be read, and we can't place every article first.

Submissions should be emailed to Steve Litt's email address, with

subject

line Article Submission. The first paragraph of your message should

read

as follows (unless other arrangements are previously made in writing):

Copyright (c) 2001 by <your name>. This

material

may be distributed only subject to the terms and conditions set forth

in

the Open Publication License, version Draft v1.0, 8 June 1999

(Available

at http://www.troubleshooters.com/openpub04.txt/ (wordwrapped for

readability

at http://www.troubleshooters.com/openpub04_wrapped.txt). The latest

version

is presently available at http://www.opencontent.org/openpub/).

Open Publication License Option A [ is | is not]

elected,

so this document [may | may not] be modified. Option B is not elected,

so

this material may be published for commercial purposes.

After that paragraph, write the title, text of the article, and a

two

sentence description of the author.

Why not Draft v1.0, 8 June 1999 OR LATER

The Open Publication License recommends using the word "or later" to

describe

the version of the license. That is unacceptable for Troubleshooting

Professional

Magazine because we do not know the provisions of that newer version,

so

it makes no sense to commit to it. We all hope later versions will be

better,

but there's always a chance that leadership will change. We cannot take

the

chance that the disclaimer of warranty will be dropped in a later

version.

Trademarks

All trademarks are the property of their respective owners.

Troubleshooters.Com

(R) is a registered trademark of Steve Litt.

URLs Mentioned in this Issue